A Model for ZLD Treatment of Blowdown from Cooling Towers—Even the Big Ones

Pilot testing under the U.S. Bureau of Reclamation’s Pitch-to-Pilot desalination research funding proved an electro-coagulation, clarification, micro-filtration, reverse osmosis with vacuum-assisted electro-distillation concentrate treatment process train can recover the saline cooling tower blowdown in a zero-liquid discharge (ZLD) configuration, preventing high-salinity wastewater from entering the sewer-shed.

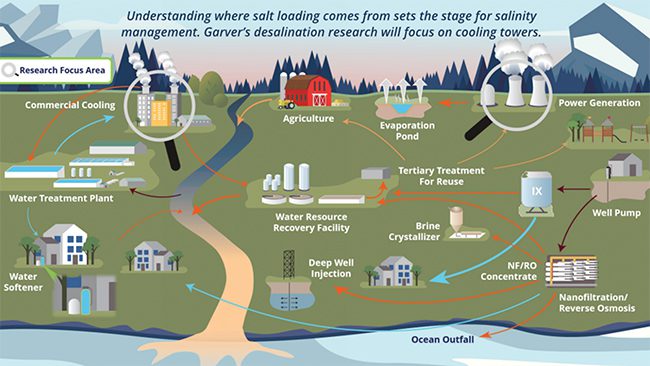

Precious water supplies are easily contaminated with salt water, but removing the salt isn’t. As shown in Figure 1, salt comes from a variety of sources. Understanding the source in a watershed sets the stage for salinity management. Often there are best management practices that can reduce salt loading, so treatment intensity can be reduced.

|

|

1. Watershed salt loading. Courtesy: Garver USA |

Power plant cooling towers (CTs) are sometimes a major salt contributor to watersheds from CT blowdown. Many industrial and commercial cooling systems utilize evaporative CTs, especially in arid regions where evaporative cooling has the highest cooling efficiency and water supply is scarce. According to the Central Arizona Salinity Study, surveys conducted by the City of Phoenix Water Conservation Department indicate that manufacturers use between 25% and 50% of their total water use for cooling.

Cooling towers are typically operated between three and four cycles of concentration (COC), which is how many times the water can be recycled before causing operational issues with scaling. Hence, the total dissolved solids (TDS) concentration entering the sewer from the blowdown is three to four times higher than the source water salinity level.

Seeing how critical CT blowdown management is to watershed health, especially in the era of indirect and direct potable reuse, Garver saw this as a perfect research opportunity. In 2019, Garver’s Denver office proposed researching an innovative process train to recover the saline blowdown from commercial and industrial CTs under the U.S. Bureau of Reclamation’s (BOR’s) Pitch-to-Pilot (P2P) desalination research funding.

Garver was one of seven teams awarded part of the $1.5 million P2P grant in November 2019 aimed at researching disruptive desalination technologies that consumed less power than what was offered on the market at the time. Garver teamed with several entities that played a significant role in project success, such as Red Rocks Community College (RRCC), Dr. Mike Mickley, and other industry partners. Collectively, those partners donated more than $480,000 of in-kind equipment, instrumentation, and labor on this $200,000 research project.

Pilot testing concluded in late November 2021, and a draft report was issued to the BOR in June 2022. Currently, the report is still in review status; however, the P2P trailer has been operating in failure mode analysis (FMA) for more than 1.5 years now. FMA results will be presented at the end of this article.

The Solution

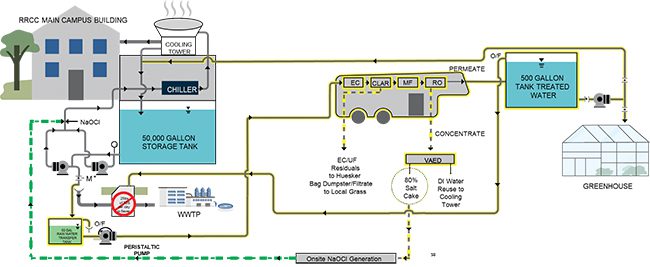

Garver proposed researching a 1.5-gallon-per-minute electro-coagulation (EC), clarification (CLAR), micro-filtration (MF), reverse osmosis (RO) with vacuum-assisted electro-distillation (VAED) concentrate treatment process train to recover the saline CT blowdown in a zero-liquid discharge (ZLD) configuration, preventing the high-salinity wastewater from entering the sewer-shed. Figure 2 shows a process flow schematic of the treatment train and how it was integrated into the existing CT system.

|

|

2. Garver’s process flow diagram for the system tested at Red Rocks Community College (RRCC) in Lakewood, Colorado. Note: NaOCl = sodium hypochlorite, EC = electro-coagulation, CLAR = clarification, MF = micro-filtration, RO = reverse osmosis, VAED = vacuum-assisted electro-distillation, O/F = overflow, M = meter, WWTP = wastewater treatment plant, UF = ultrafiltration, and TDS = total dissolved solids. Courtesy: Garver USA |

Water quality of the treated permeate and distillate was analyzed to determine if it could be repurposed for CT makeup dilution water to balance water chemistry. The salt slurry from the VAED system was evaluated to see if it was pure enough to use as a feedstock for onsite sodium hypochlorite generation to use in the CT and promote a circular economy.

The goal of this project was to prove that an EC/CLAR/MF/RO with VAED concentrate treatment system could be effective in treating high-TDS commercial CT blowdown from the 600-ton evaporative cooling system located at RRCC’s Main Campus Building in Lakewood, Colorado. The RRCC CT operated at three to four cycles of concentration.

The Research

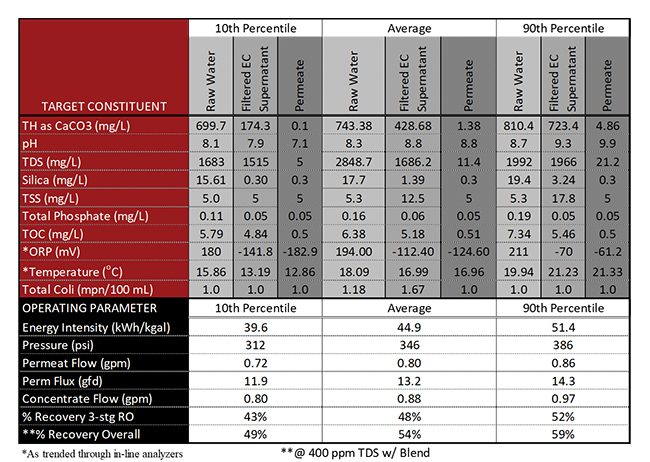

As shown in Figure 2, the purpose of EC is to precipitate the constituents in the CT blowdown that could foul the CT and the RO membranes used to treat the blowdown (refer to Table 1 for a list of these major constituents). EC is an alternative method of adding a metal coagulant without adding a salt counter-ion by using direct-current and metal electrodes.

|

|

Table 1. Water quality data. Courtesy: Garver USA |

Under a direct current, the metal anode dissolves into the water, adding the metal coagulant to the water while hydroxide is generated at the cathode. A ferric hydroxide or aluminum hydroxide “sweep” floc is formed depending on what blades are used. The MF system polished the pin-floc from the EC supernatant that did not settle in the clarifier and would otherwise foul the RO. By design, if the pre-treatment train was effective at removing the common foulants prior to the RO, the RO would perform at a higher specific flux (gallons/ft2/day [gfd]/psi) and recoveries without damaging the membranes.

The concentrate from the RO was sent to a holding tank where the VAED system would treat the 2,200 milligram per liter (mg/L) to 4,100 mg/L TDS in eight-gallon batches. The VAED system is a patented distillation process for spent brine treatment from water softeners that combines alternating-current EC and vacuum distillation into one unit process. It flashes high-TDS water and condenses the steam into low-TDS condensate, leaving an 80% (by weight) salt slurry. Modifications were made to the water softener spent-brine treatment VAED system, donated by Salt Miner LLC, to accommodate the 3 to 5 gallons per hour (gph) of concentrate from the RO. The standard unit is sized for 1 gph of softener spent brine that can exceed 120,000 mg/L TDS.

Rockwell Automation power quality monitors were installed on each component of the process train to read kW and kWh. Endress Hauser pico-mag meters and in-line water quality analyzers were installed throughout the process to trend total flow, instantaneous flow, conductivity, pH, oxidation reduction potential (ORP), and temperature. Together, this instrumentation allowed the team to trend kWh consumed per 1,000 gallons (kgal) treated and the treatment efficacy in real-time.

The Results

Throughout the field testing, parameters were adjusted in the EC process train such as hydraulic residence time (HRT), electrode material, electrode jumping configuration, amperage density, pre-treatment chemistry for pH, and downstream filtration micron removal size. RO permeate flux and permeability were challenged based on the various EC configurations and the fact that the three-stage RO only had one 29-ft2 element in each stage due to budget constraints. Typically, a three-stage RO has multiple elements in the first stage and decreases in number as you increase the number of stages. Electrode configuration, amperage density, re-seeding of salt slurry, and condensation energy adjustments were made to the VAED system throughout testing.

Shown in Table 1, the main treatment train consistently met water quality goals and resulted in high TDS removal efficacy without fouling the RO membranes. The main treatment train was operated three to five hours a day for three days a week between August 2021 and December 2022. After each RO run, the membranes were forward flushed with eight to 10 gallons (<1% of processed flow) of 10 mg/L TDS permeate until the concentrate conductivity was within 20% of the permeate feed flush conductivity.

Since VAED utilizes ohmic heating to heat the brine, the higher the conductivity, the quicker it gets hot. For the donated VAED system to operate with the existing electrode configuration on the lower-TDS concentrate (as opposed to the higher-strength water softener spent brine it was originally designed for), it needed the addition of rock salt to bring the TDS from what was leaving the third stage as concentrate to about 56,000 mg/L TDS. Otherwise, it would take much longer to upcycle the salt to allow the electro-distillation process to occur efficiently.

Notable Trends

The following findings were obtained through the testing:

- Due to the high hardness, polarity reversal frequency of the EC unit needed to be reduced from once per minute to four times per minute to extend runtime between clean-in-place procedures and prevent scaling.

- Increasing the pH with sodium hydroxide from 8.6 to between 9.7 and 10 resulted in total hardness (TH) removal efficacy between 72% and 95% after the EC in the presence of anti-scalants. Only 40% to 64% hardness removal was realized at ambient pH of 8.6.

- For three weeks in November 2021, average TH concentration entering the RO units was 595 mg/L as CaCO3 with four of the sample days exceeding 700 mg/L TH. The membranes recovered within 94% of the initial flux values after a 10-gallon permeate flush.

- Regardless of pH or residence time, the EC unit removed between 67% and 98% of silica.

- In all tests, EC depressed the ORP from > 220 millivolts (mV) to between –90 mV and –140 mV indicating a reducing condition and the absence of oxidizers.

- A one-minute EC residence time with ambient pH resulted in one of the best performing RO runs where the system was operated between 600 psi and 640 psi, and fluxes between 15 gfd and 17 gfd, while not irreversibly fouling the membranes. Combined permeate conductivity remained < 20 microsiemens/centimeter (µS/cm), about 13 mg/L TDS.

- The VAED system removed 98% to 99% of the TDS for three lab analysis dates where the raw TDS was between 100,000 mg/L and 186,060 mg/L at an energy intensity of 1,750 kWh/kgal and 620 kWh/kgal, respectively.

- The higher the conductivity, the more aggressive the boil in the VAED flash chamber due to ohmic heating and the lower the energy intensity value.

- Significant improvements can be made to the VAED cooling system to increase the throughput and decrease the energy intensity.

Unanticipated Positive Consequences of Failure Mode Analysis

After the last test was performed on the P2P trailer in late November 2021, the system was put into failure mode analysis (FMA). The system was left static from December 2022 to early March 2022 without performing the standard RO pickling routines. After performing only a 20-gallon permeate rinse, the system’s specific flux recovered to its initial value under the standard configuration without any chemical pretreatment, just EC + CLAR + MF.

Subsequent FMA testing further challenged the process train by operating in a batch mode where the concentrate was recycled in a proprietary configuration. In this mode, recovery went from approximately 54% to 97% without fouling, the need for chemical pre-treatment, or the need for permeate rinses. Later during the FMA, the trailer was only operated an average of once a month, without suggested downtime maintenance implementation to the EC, MF, and RO system. This high of a recovery allowed the process train to close the ZLD loop with the addition of the VAED system.

Conclusions

Proof of the EC/CLAR/MF/RO with VAED concentrate treatment train was achieved. EC was a successful alternative mechanism for foulant precipitation and created ideal water quality for RO membranes without the use of anti-scalants or pH depression. Throughout piloting and FMA, RO fouling was not noticed since the specific flux was consistently recovered.

Automation of the pilot trailer should be considered in future testing to allow for continuous operations. Although the EC and VAED performed well, more research behind the removal mechanisms, and optimization of full-scale design constraints, capital costs, and operational costs would be beneficial to the advancement of this technology as a commercialized solution to manage salt loading.

Dr. Peter Fiske, executive director of the National Alliance for Water Innovation (NAWI), said, “This demo is an excellent opportunity to see the sort of small-scale, distributed desal system NAWI seeks to develop and advance with both its pilot program and our overall baselining and roadmapping.”

—Eric Dole, PE is the Water and Energy Practice Lead for Garver USA’s Water Team.