OTEC, a Long-Stalled Baseload Ocean Power Technology, Is Seeing a Swell

A project to deploy a 1.5-MW commercial-scale ocean thermal energy conversion (OTEC) platform in the African island nation of São Tomé and Príncipe by 2025 has gained a key design certification. The crucial milestone directly addresses technical risks that have hampered OTEC, a long-pursued baseload offshore renewable technology.

UK-based firm Global OTEC Resources in April received its first certificate of approval for the methodology of installation of a cold-water riser—a pipe used to transport seawater from the ocean to the seawater tank and vice versa from an offshore OTEC platform (see sidebar below). The certificate was granted by marine warranty surveyor ABL Group, which provides independent third-party technical reviews for high-risk marine construction and transportation projects. The milestone “is particularly important given the technical challenges faced by OTEC installations, and the long history of OTEC’s unsuccessful implementations,” noted Global OTEC.

“History is an important teacher, and we are committed to learning from it,” said Global OTEC Founder and CEO Dan Grech. “Failure of previous OTEC projects highlights where we should exercise caution, so third-party technical due diligence from the earliest stage is important for our success,” he said.

|

|

1. Global OTEC has designed what it says will be the first commercial-scale ocean thermal energy conversion system. The 1.5-MW floating platform named Dominique is set to be installed in São Tomé and Príncipe in 2025. Courtesy: Global OTEC |

Poised to Become the First Commercial-Scale OTEC System

Global OTEC’s flagship project is the “Dominque,” a floating 1.5-MW OTEC platform set to be installed in São Tomé and Príncipe in 2025 (Figure 1). The company says the platform “will be the first commercial-scale OTEC system.”

That’s significant because OTEC is a technology that was proposed as far back as 1881 by French physicist Jacques Arsene d’Arsonval for converting solar radiation absorbed into the ocean to electrical power. OTEC has been proven to provide continuous power as well as fresh drinking water and cold water for refrigeration. But while more than a dozen prototypes have been tested intermittently since the first experimental 22-kW low-pressure turbine was deployed in 1930, no commercial-scale plants exist.

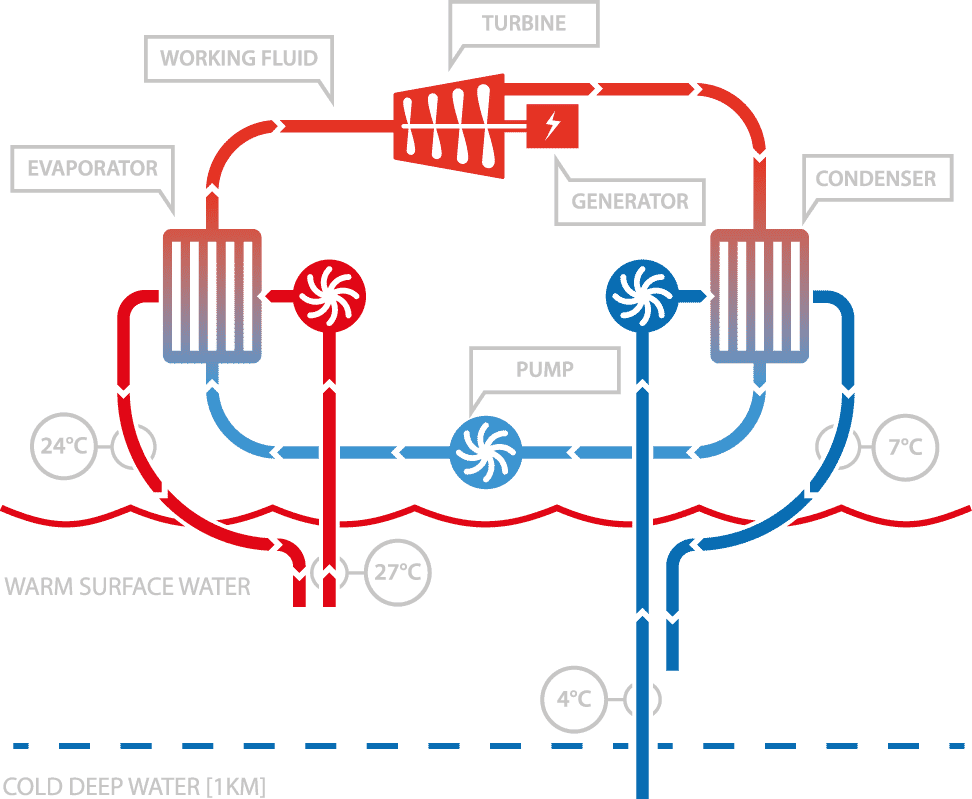

OTEC essentially seeks to exploit the ocean’s thermal gradients—temperature differences of 36F or more between warm surface water and cold deep seawater—to drive a power-producing cycle. “Since the ocean comprises around 70% of the earth’s surface it is a vast receiver and repository of solar energy. While waves, winds, tides, and currents are all forms of ocean renewable energy, which vary with time and season, conversely, an OTEC system permits the generation of constant power 24 hours a day, 365 days a year,” explained the International Energy Agency’s (IEA’s) Ocean Energy Systems (OES) technology collaboration program in an October 2021 white paper.

The Swell of Interest and Activity in OTEC

Existing prototypes have typically conformed to three basic configurations depending on their location: on land, relatively a short distance from the coast; mounted on the edge of a continental shelf; or on a floating platform or ship, where deep cold water can be accessed directly underneath the hull.

In addition, OTEC typically leverages three main types of power generation systems: a closed cycle, an open cycle, or a hybrid of the closed and open cycles. In a closed OTEC cycle system, ammonia—as a liquid with a low boiling point—is pumped into an evaporator (heat exchanger) that is heated by warm seawater, causing the working fluid to expand in a generator-driving turbine. The expanded vapor is then condensed back to a liquid using cold seawater in another heat exchanger. In an open cycle, the seawater itself functions as the thermodynamic fluid after it is “flashed” into steam in a partially evacuated chamber. The steam is then used to drive a steam turbine, and exhausted vapor is condensed using cold seawater.

According to the IEA’s OES, one of the world’s most significant tests was the U.S. Department of Energy’s floating OTEC-1 project, a 1-MW closed cycle test loop that ran between 1980 and 1981. The project proved the feasibility of horizontal launching, towing, and successfully mating to the underside of a converted U.S. Navy tanker a bundle of three high-density polyethylene (HDPE) cold water pipes (CWPs), plus later disconnection, using a special motion decoupling gimbal. It “provides confidence that if, in particular, the skills of the oil industry are utilized, it is possible to design and install successfully larger CWPs,” which have posed a “key uncertainty for OTEC,” OES said.

What Is a Riser Pipe?“A riser pipe is a vertical pipe that moves fluid from one location to another, in our case, this is from below the ocean’s surface, to the surface,” explains Global OTEC Resources. “OTEC risers can come in many forms, they can be made out of a flexible tube, seawater-resistant metal alloys, or concrete, and some testing has even been performed on composite materials such as glass fiber.”

The cold-water risers for a large-scale OTEC generation need large diameters to allow enough water flow rate for the heat exchangers, the company noted. “These risers can be several meters (m) in diameter and exceed 750 m in length. Some locations require as high as 1,400 m.” The risers also “need to withstand the vessel motions as the boat moves with the wind and waves, while the pipe tries to remain static; lateral forces of the ocean current which can extend far down towards the seabed; and long-term cyclic loads caused by the issues above.” Designing resilient risers has posed an enduring challenge that has long-hampered OTEC’s commercial feasibility. “These installations have planned installation lifetimes of tens of years, so designing the riser to withstand all these forces for that long can be very challenging,” noted Global OTEC. “Failure of the cold-water pipe would prevent the OTEC cycle from working, causing loss of power and, depending on the location of the break, could pose a danger to the vessel itself.” |

More recent notable projects include Makai Ocean Engineering’s land-based 105-kW OTEC plant at a research center in Hawaii, and a 20-kW OTEC floating pilot plant spearheaded by the Korean Research Institute of Ships and Ocean Engineering (KRISO) that began operating in 2012. KRISO is now developing a 1-MW OTEC demonstration in the small Pacific Island of Kiribati based on a trial operation of a system tested in South Korea’s East Sea (near Pohang, Figure 2).

“The 1-MW OTEC demonstration was designed for 24-degree-C seawater temperature difference and has successfully carried out in a trial operation (output of 338 kW under operating condition of 18.7-degree-C temperature difference) in Korea,” Dr. Hyeon-Ju Kim, a KRISO principal researcher, told OES in a July 2022–published interview. “If the demonstration of the 1-MW OTEC plant near the equator is successfully carried out in the future, competent professionals can draw a positive outlook on the scale of 10-, 100-, and 400-MW OTEC plants gradually.”

OTEC development is also making headway in Japan, where in 2016, a 100-kW OTEC demonstration on Kume Island, Okinawa Prefecture, was connected to the grid. OTEC power generator Xenesys, which runs and maintains the project for Okinawa Prefecture (Kumejima Town), alongside project partners Japanese transportation firm Mitsui O.S.K. Lines (MOL) and Saga University, confirmed the demonstration (Figure 3) is still operating.

In March 2023, the partners gained the backing of Japan’s Ministry of the Environment under a technology development program for “regional symbiosis and cross-sectoral carbon neutrality” to expand the OTEC project to a commercial-scale 1 MW “by around 2026.” The effort will entail manufacturing large, parallel-type titanium heat exchangers equivalent to 200 kW of power generation and verifying their performance from fiscal year 2022 to 2024, aiming to establish large-scale heat recovery technology from seawater for the commercialization of OTEC, the companies told POWER.

|

|

3. An ongoing 100-kW ocean thermal energy conversion (OTEC) demonstration facility owned by Japan’s Okinawa Prefecture is slated to be expanded into a commercial-scale 1-MW facility. Courtesy: Mitsui O.S.K. Lines |

The Quest: Offshore Renewable Baseload Power

MOL lauded OTEC’s potential as a baseload power resource that is “not greatly affected by weather conditions.” Another noted benefit is that “even after deep ocean water is used for power generation, the water quality is unchanged, and the temperature is still low enough to be used for secondary purposes such as fisheries, agriculture, and air conditioning.” While MOL acknowledged unsuccessful attempts globally to commercialize the long-latent technology, it said that its efforts “to quickly commercialize OTEC in Japan and overseas,” would be bolstered by a project to verify its research from the Okinawa demonstration at a project in Mauritius.

“Mauritius established a road map to raise its percentage of renewable energy to 60% by 2030,” the company noted. “OTEC, which can reliably generate power 24 hours a day regardless of weather conditions, has great potential in Mauritius, thanks to the island’s advantageous geographical location in the Indian Ocean. Secondary use of seawater after power generation can also help other industries on the island.” MOL said it also plans to use the “knowledge and expertise it has accumulated through its offshore business and supply chain network,” to boost OTEC commercialization.

Global OTEC also lauds OTEC’s potential for small island developing states (SIDS). SIDS often suffer high energy prices, owing to a reliance on diesel and other fuel imports, and face space constraints to install adequate amounts of wind and solar. Along with baseload power, “OTEC can supply quantities of cold water as a by-product. This can be used for air conditioning and the nutrient-rich deep water can be used for aquaculture and the creation of a sustainable local economy,” said Neil Reynolds, Global OTEC board director, who is also a special advisor to the international organization SIDS DOCK. “OTEC can also be coupled with desalination for drinking water and the production of ammonia and green hydrogen,” Reynolds added.

Along with its first closed-loop barge planned for São Tomé and Príncipe, off the western equatorial coast of Central Africa, Global OTEC is exploring OTEC sites in the Turks and Caicos Islands (TCI), an archipelago of 40 low-lying coral islands in the Atlantic Ocean. “Having a vast exclusive economic zone of ocean space many multiples the area of their land waters and being in the tropics, TCI is well suited for OTEC,” the company said. Global OTEC’s desktop studies have shown TCI possesses the ideal combination of warm seawater all year round and easy access to cold deep water with continental shelves quickly falling to 1,000 meters (3,281 feet) within 4 kilometers of the shore.

Addressing a Crucial Challenge: Cold-Water Riser Pipes

Global OTEC acknowledged, however, that launching its first commercial project, the Dominique, will require trailblazing a deployment pathway that directly addresses risks that have long hampered OTEC. The most prominent one relates to cold water riser pipes (see sidebar above, “What Is a Riser Pipe?”), which furnish OTEC installations with the significant amount of cold water they require.

Global OTEC says it chose a floating barge design because onshore OTEC plants “require several multi-kilometer pipes fixed to the seabed” to facilitate the acquisition and safe discharge of water. Water pipes, it noted, “represent one of the largest cost centers of an OTEC plant.” Onshore OTEC, which effectively centralizes power production, also limits the regions where the process can be economical, and it presents a single point of failure in the event of a natural disaster.

Along with thoroughly vetting its risks related to OTEC riser pipes—through third-party technical reviews—the company says it has pursued a rigorously detailed design phase for the cold-water pipe “in collaboration with suppliers and scientists on the cutting-edge of subsea riser pipe designs.” To further curb risks, it will deploy its first commercial systems “in a market where much smaller distances between warm surface seawater and cold deep water are present,” it said.

Given economies of scale, smaller fledgling systems will be costly, Global OTEC acknowledges. Citing literature reviews of previous OTEC plant designs, the company points to a levelized cost of energy (LCOE) for large-scale plants of $0.05/kWh. “Our procurement studies and engagement with suppliers show a range between $0.30 and $0.15 per kWh is realistic for early generations of OTEC barges,” it said.

However, recent changes in the global economics of energy and advancements in the efficiency of OTEC components may improve cost, it noted. “Historically, the efficiency of the cycles and components proved difficult for early projects to make a commercial case. Throughout decades of very cheap oil, gas, and coal, it was thought that OTEC projects needed to be 50 MW or even 100 MW scale to be competitive,” it noted. While the company predicts that early commercial OTEC systems may still need “innovative funding models to succeed,” it appears confident that conditions imposed on global power systems by the energy transition may present the “perfect storm” to begin commercialization of OTEC.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).