Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager…

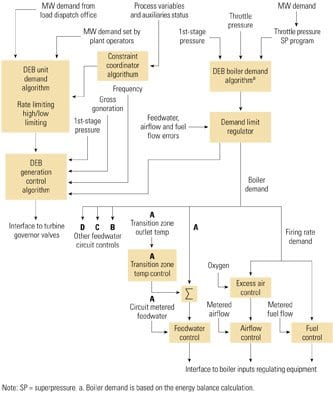

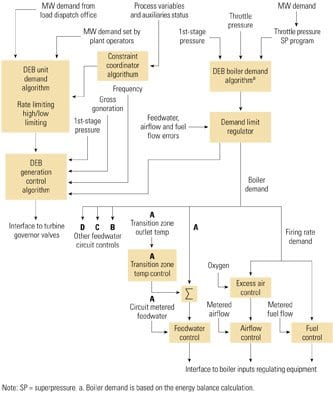

Power plant security issues. Latest developments and case studies of new and retrofit power plant digital and wireless instrumentation and control systems

Age is wreaking havoc on the U.S. generation industry, especially the coal-fired sector. Industry conferences are replete with hand-wringing over the "brain drain," the lack of skilled personnel, the meager…

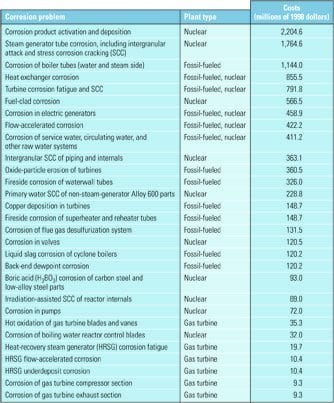

U.S. power producers and owners of industrial steam systems each spend about $15.4 billion annually to combat corrosion in their plants. Scale and deposits are thought to be responsible for…

Rotary regenerative air heaters capture and recycle about 60% of the heat energy exiting the boiler—energy that would otherwise go up the stack. For a 500-MW coal-fired plant, the recycled…

Earlier this February, Siemens Power Generation's (SPG's) factory in Berlin delivered its 500th gas turbine. The SGT5-4000F (Figure 2), formerly called the V94.3A, is nominally rated at 270 MW and…

Each day, American Ref-Fuel's Massachusetts facility converts some 3,500 tons of municipal waste to electricity and transmits it to the regional grid. Three boilers and two turbines operate around the…

The drivers may be different, but the destination—higher efficiency—is the same worldwide. As a primary component of current efforts to reduce the environmental impact of burning low-cost coal, new and…

Refractory is an integral part of boilers. In the steam-generating industry, refractory materials are used to fill gaps and openings (to help keep the fire inside the firebox), to line…

Catalyst management refers to a comprehensive methodology for predicting when catalyst layers should be replaced or regenerated, or a new layer added, based on catalyst deactivation rates, performance requirements, and…

The goal of the Clean Air Interstate Rule (CAIR) signed into law almost a year ago is to reduce NOx emissions by 60%, relative to 2003 levels, across 28 eastern…