Consortium Exploring Ammonia Retrofit to GE Gas Turbines in Singapore

Singapore-based Sembcorp Industries, GE Vernova, and Japanese heavy industry firm IHI Corp. will jointly examine potentially retrofitting two GE 9F gas turbines at an 815-MW gas-fired combined cycle power plant in Singapore with ammonia capabilities.

The companies on Oct. 25 revealed they signed a non-binding memorandum of understanding (MoU) to assess ammonia combustion capabilities at the Sembcorp’s Sakra power plant. The cogeneration plant in Pulau Sakra on Jurong Island, southwest Singapore, which opened in November 2001, produces power for the grid and process steam for chemical and petrochemical facilities nearby.

An Evolving Collaborative Venture

The companies’ efforts to explore ammonia combustion stem from separate collaborations. In 2022, IHI and Sembcorp said they would explore developing an integrated “green” ammonia supply chain, focusing on both upstream and downstream elements. IHI and Sembcorp notably set out to study the introduction of an ammonia-fired gas turbine as well as to convert Sembcorp’s two existing Jurong Island gas-fired assets to ammonia.

GE and IHI, meanwhile, in 2021, signed an MoU to define an “ammonia gas turbine business roadmap,” which intends to support the use of ammonia as a carbon-free fuel in existing and new gas turbines. Under the MoU, the companies agreed to conduct research on the marketplace volume of ammonia, as well as feasibility studies for ammonia as feedstock for gas plant installations in Japan and Asia. In January 2023, notably, GE and IHI companies signed another MoU to develop ammonia combustion technologies by 2030 that could enable GE’s F-class heavy-duty gas turbines (6F.03, 7F, and 9F gas turbines) to fire up to 100% ammonia.

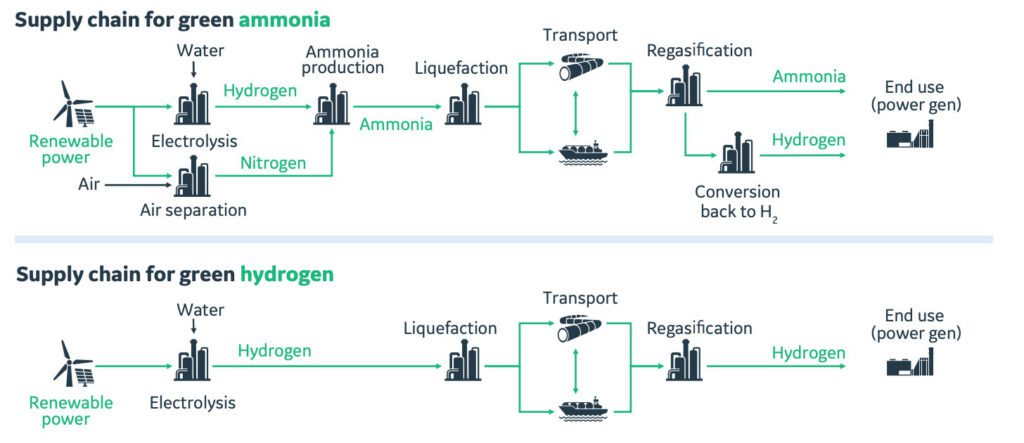

As part of that MoU, GE and IHI conducted a joint year-long Japan-focused study, mapping a value stream for hydrogen and ammonia from their points of production to their point of use as fuel in a power-generating gas turbine. As POWER reported earlier this year, the study suggests that ammonia could be a potentially lower-cost alternative fuel for gas turbines in Japan than liquid hydrogen if the full import value stream is considered.

Ammonia: a Challenging but Promising Fuel

Experts have noted countries with limited direct access to sources of low-carbon power could use ammonia as a vector for hydrogen imports, because ammonia has a high hydrogen content per unit volume, and it is easier to liquefy than hydrogen (–33C versus –253C for hydrogen). Storage and pipeline distribution systems for liquefied-ammonia storage facilities are built out in the U.S. and other countries.

And ammonia, already abundantly produced, can also be cracked from hydrogen, either produced via electrolysis using low-carbon power sources or “blue” hydrogen. If synthesized from pure hydrogen for use in gas turbines, it can also be combusted, directly fed into, or co-fired at existing coal plants or gas turbines. Like hydrogen, it can also be used as a seasonal storage medium for the power sector, offering a potentially cheaper alternative to batteries.

Ammonia, notably, is already a key chemical used in selective catalytic reduction (SCR) systems to reduce nitrogen oxides (NOx) in many power plants, though deploying it as a fuel could increase its required amounts by a factor of 400 to 600, depending on the gas turbine and plant configuration, GE suggests in a recent white paper. Ammonia combustion, meanwhile, remains challenging, because it is a much more reactive fuel than natural gas and might reduce flame stability.

Another critical challenge relates to ammonia’s combustion’s high NOx production. “During the process of combustion in a gas turbine configured with a current DLN (dry low NOx ) combustion system, the nitrogen in ammonia tends to convert to nitric oxides (NOx ) at a rate of ~100X more than in methane or hydrogen flames at the same flame temperature. This will yield NOx emissions in excess of 1000 ppm. This is even true with blends of ammonia and natural gas,” GE notes. Finally, owing to operability and safety concerns, a start-up fuel may be required, and because ammonia is toxic, it could require new power plant safety systems.

The Goal: Deploying an Ammonia-Capable Gas Turbine by 2030

These inherent challenges will require additional engineering, GE told POWER on Friday. For now, research and development is ongoing for a retrofittable 100% ammonia-capable combustion system that would be compatible with certain GE turbine models, it said. “Technical experts from both GE and IHI have engaged in discussions about the combustion technology, including both development and validation requirements,” it said. “The team is working with the roadmap to enable this by 2030,” it said.

GE added that while its new MOU with Sembcorp and IHI does not set a specific date, GE expects it could “start the required exploration with Sembcorp and IHI in 2024.” The exploration will prominently focus on identifying modifications that will be necessary on Sakra’s 9FA gas turbines to enable ammonia combustion. “The modifications would include the combustion system, associated fuel accessories, and controls,” GE said.

“Depending on the results of the combustion technology development, upgrades may be required to the emissions after-treatment (i.e., SCR) systems to account for potential increases in NOx emissions,” it added. Other modifications could involve “upgrades to other plant safety systems due to toxicity issues associated with using anhydrous (i.e., pure) ammonia. Many power plants use ammonia as a feedstock for their SCR systems, but that is usually aqueous ammonia,” it explained.

Decarbonization a Major Driver in the Quest for an Ammonia Value Chain

For Sembcorp, the potential retrofit of Sakra, a regional powerhouse, is rooted in the global company’s quest for low-carbon energy. Ammonia combustion could also “bolster industry confidence for the development of an ammonia value chain in Singapore,” it said.

When the $650 million Sakra plant was commissioned in 2001, it was the first independent power producer in Singapore, as well as the country’s largest and most efficient cogeneration plant, the company noted. “We are now taking the next step to support decarbonization efforts through the potential retrofitting of the power plant with ammonia-firing capabilities,” said Koh Chiap Khiong, CEO of Sembcorp’s Singapore & Southeast Asia segment. “As the pioneer in adopting technologies to reduce carbon footprint, Sembcorp remains committed to decarbonizing the power generation sector.”

IHI views the collaboration as another opportunity to build out an ammonia value chain. The company is already leading several notable projects. In June 2022, IHI said tests to mono-fire liquid ammonia in a newly developed combustor installed on a 2-MW class IM270 gas turbine yielded a greenhouse gas reduction rate exceeding 99%, “even when the ammonia fuel ratio is at 70~100 %.” IHI, so far, also has agreements to explore supply chain prospects or undertake ammonia co-firing with companies in Japan, Indonesia, Malaysia, the United Arab Emirates, India, and Australia.

“IHI is developing ammonia combustion technologies and infrastructure solutions that can be safely retrofitted to existing power generation facilities, thereby establishing true reductions in carbon emissions,” said Jun Kobayashi, IHI Corp. board director and managing executive officer. “The ability to retrofit such technologies also provides decarbonization pathways that future-proof existing investments in power generation.”

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).