Centrus, Oklo Set Out to Solidify HALEU Fuel Cycle, Trade Advanced Nuclear Power and Fuel

Centrus, a firm poised to demonstrate high-assay, low-enriched uranium (HALEU) production, will partner with microreactor technology developer Oklo on several pioneering steps to build out the HALEU front-end supply chain, including pivotal commercial deconversion capabilities. The landmark collaboration could also make Centrus one of Oklo’s first commercial power off-takers for two reactors planned in Southern Ohio and furnish Centrus with a committed HALEU customer.

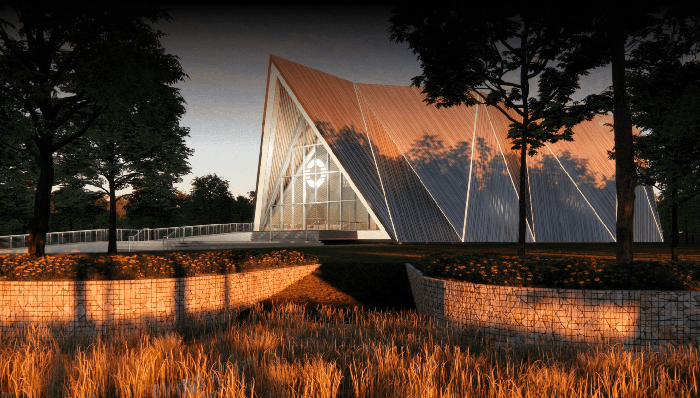

Centrus is notably set to begin first-of-a-kind HALEU production at its American Centrifuge Plant cascade located on the Department of Energy’s Portsmouth Gaseous Diffusion Plant (PORTS) reservation in Piketon, Ohio, by the end of 2023. Oklo in May announced it would build its second and third commercial 15-MWe Aurora Powerhouse reactors on a PORTS land parcel nearby that the DOE in 2018 transferred to community reuse organization Southern Ohio Diversification Initiative (SODI). Under a memorandum of understanding (MOU) announced on Aug. 28, the two companies said they would boost a collaboration first cultivated in a November 2021 letter of intent to make Southern Ohio a “critical hub for the future of the U.S. nuclear industry.”

Lucrative Offtake Potential for Proposed Ohio Microreactors

Under the MOU, Centrus intends to enter into one or more definitive agreements to buy power from Oklo’s Aurora powerhouses planned in Piketon. While details are not public, Oklo suggested the sale could involve a long-term power purchase agreement. Pivotally, it could mean that “Oklo would power the enrichment for its fuel production for future plants,” the company told POWER. Centrus, meanwhile, intends to sell HALEU from its Piketon production facility to Oklo. Oklo said a deal could entail “specific” and “sizable” quantities. “The HALEU production plant is designed to be scaled up to support hundreds of reactors,” it noted.

The two companies on Monday also said they would collaborate to “manufacture components” for Oklo’s Aurora powerhouse at Centrus’s advanced manufacturing facility in Oak Ridge, Tennessee, as well as manufacturing capacity at the American Centrifuge Plant in Piketon, Ohio. “Centrus has a breadth of capabilities, and we are exploring a variety of components that could be well suited for Centrus’ capabilities,” Oklo noted.

Centrus is currently readying to produce its first batch of HALEU uranium hexafluoride (UF6, 19.75% enriched) under a multiphase agreement with the DOE awarded in November 2022. Phase 1 of the contract calls for the completion of Centrus’s American Centrifuge Plant cascade and the start of operations to produce an initial 20 kg of HALEU UF6 (19.75% enriched) by December 31, 2023. Under Phase 2, Centrus plans to continue production for a full year at an annual production rate of 900 kg of HALEU. The company in February 2023 completed construction and initial testing of its advanced uranium enrichment centrifuge cascade as well as most of its associated support systems, and in June 2023, it got the Nuclear Regulatory Commission’s (NRC’s) green light to introduce UF6 into the cascade.

The DOE will own the HALEU produced from the demonstration cascade, but the operation contract also gives the DOE options to pay for up to nine additional years beyond the base contract (though those options will be subject to the availability of Congressional appropriations). However, Centrus is separately also exploring the possibility of scaling up the Piketon facility for expanded HALEU production. The company has said that provided it can secure sufficient funding or off-take contracts, a full-scale HALEU cascade—consisting of 120 individual centrifuge machines with a combined capacity of approximately 6,000 kg of HALEU per year (6 MTU/year)—could be brought online within about 42 months. “Centrus has the capability to add an additional cascade every six months after that,” it said.

Collaborating on Deconversion Capacity

As part of the MOU, Centrus and Oklo on Monday also announced they would collaborate “to establish and license the capabilities necessary to deconvert HALEU from uranium hexafluoride to uranium metal and fabricate fuel assemblies for Oklo’s Aurora powerhouses.”

If accomplished, that effort would mark a significant step in the development of a HALEU front-end supply chain. While Russia is the world’s only commercial supplier of HALEU, recent geopolitical concerns have posed critical supply bottlenecks of the fuel material that will be required for many advanced reactor designs. According to the DOE, domestic HALEU production is currently dependent on “downblending,” which involves blending existing or recovered highly enriched uranium (HEU) to uranium of a lower enrichment. However, limited HEU stocks are available for downblending beyond those obligated to the National Nuclear Security Administration (NNSA).

Uranium enrichment, another option, involves “enriching” the U-235 isotope in a multi-step process. Mined uranium consists of about 99.3% U-238 and 0.7% U-235, which is fissionable when enriched to beyond 3% (as well as less than 0.01% of U-234). At a conversion plant, uranium oxide is converted from powder into a UF6, a gas whose fluorine element does not contribute to the weight difference while separating U-235 from U-238. During enrichment, the UF6 gas is separated into two streams, one with more U-235 than before and the other with less. Centrus and Urenco utilize gas centrifuge technology, which uses many rotating cylinders connected in long lines to create a strong centrifugal force. The centrifuges move heavier U-238 to cylinder walls, while lighter U-235 collects near the center. While typical light water reactor (LWR) fuel requires enrichment of U-235 to between 3% and 5%, HALEU enrichment needs ranges of between 5% and 19.75%.

But after enrichment, the UF6 must be “deconverted” to a uranium form (to include oxides, metal and alloys, and nitrides and carbides) suitable for fuel fabrication (for more, see sidebar, “What Is HALEU Deconversion?”). In the conventional fuel cycle, this step is traditionally done in fuel fabrication facilities. However, a HALEU supply chain will require accommodating different fuel forms for advanced reactors. It also presents significant difficulties—with safety and economic implications—associated with transporting HALEU in UF6 form. Deconversion of HALEU enriched to 10% or higher, notably, must also be conducted in a physical security Category II facility. Those factors are playing out in an industry debate about whether or not it would be more feasible to co-locate HALEU deconversion capabilities at the point of enrichment.

The DOE, meanwhile, is also exploring feasible options. On June 4, it launched a draft request for proposals to support its aim to acquire domestic deconversion services as part of a broader effort to stimulate a diverse, domestic commercial supply and demand for HALEU. “DOE has determined that the domestic capability to enrich uranium as UF6 up to <20% by weight of the isotope U-235 and subsequently deconvert it is required as part of the temporary HALEU demand it aims to establish,” the agency noted.

While HALEU UF6 deconversion is not novel—it has traditionally been performed at national laboratories like INL to fabricate metallic fuel for high-performance research reactors—establishing commercial HALEU deconversion will require relevant licensing. According to Dr. Charlyne Smith, a nuclear fuel expert at the Breakthrough Institute, applicable regulations include 10 CFR 40 (Domestic Licensing of Source Material), 10 CFR 70 (Domestic Licensing of Special Nuclear Materials), and 10 CFR Part 71 (Packaging and Transportation of Radioactive Material).

“I think some primary regulatory challenges include [first,] the demonstration of adequate nuclear non-proliferation safeguards, [and second,] demonstrating safety and environmental impact of a commercial deconversion facility to ensure protocols that minimize potential risks associated with chemical reactions, criticality and radiation exposure, as well as protocols for preventing contamination and effective waste management,” she said. “Another more obvious challenge is financing a capital-intensive facility with deconversion capabilities.”

What Is HALEU Deconversion?High-assay, low-enriched uranium (HALEU) deconversion involves transforming uranium hexafluoride (UF6) gas into metallic uranium or other uranium compounds for fuel fabrication. But because “metallic fuels can’t be directly formed from UF6, the process involves a series of chemical reactions to turn UF6 gas into solid form,” Dr. Charlyne Smith, senior nuclear energy policy analyst at the Breakthrough Institute, explained. “Generally, the first step is hydrolysis, which means adding water vapor to the UF6 gas to form uranyl fluoride (solid) and hydrogen fluoride (UF6 + 2H2O —> UO2F2 + 4HF). The uranyl fluoride is what is useful from this point forward,” she said. “The next step is to remove the fluoride atoms using hydrogen as a reducing agent to produce uranium dioxide in solid power form (UO2F2 + H2 —> UO2 + 2HF). The uranium dioxide power is the key ingredient to prepare metallic fuel whether you’re fabricating uranium-zirconium (U-Zr), uranium–molybdenum (U-Mo), uranium silicide, (U3Si2), or any other metallic fuels.” Production of HALEU U-Zr–based metallic fuels would require mixing and evenly distributing the UO2 powder and zirconium hydride powder (ZH2) in precise portions, Smith said. “This makes it easy to next compact the powders to a specific shape, whether it is a fuel pellet or plate (depending on reactor design). Once it’s been compacted in a specific shape, then it is sintered, meaning the pellet or plate is heated to very high temperatures in a controlled environment to fuse the particles together and increase the density of the fuel.” The last steps involve cladding and sealing the fuel with a protective material that will prevent contact between the fuel and the reactor coolant. “We want that cladding to be corrosion resistant,” Smith said. “Of course, the fuel will undergo quality assurance before assembly.” |

A Strategic, Wide-Ranging Partnership for Oklo

For Santa Clara, California–based Oklo, the collaboration with Centrus provides a clear direction on feasibly developing a pathway to commercial operation for its Aurora Powerhouse and begin positioning it to meet soaring nuclear demand. The Aurora Powerhouse is a vertically oriented compact passive fast-spectrum reactor derived from the Experimental Breeder Reactor-II (EBR-II) that uses liquid metal as a coolant. While the company has so far marketed a 1.5-MWe microreactor version of the Aurora, it has now expanded its capacity offerings from 15 MWe to 100 MWe. The compact fast reactor uses a HALEU metallic uranium-zirconium fuel enriched to about 19%.

Since launching its Aurora design in December 2019, Oklo has marked a quick succession of milestones both for technology and fuel development, effectively gaining a reputation for trailblazing in the burgeoning advanced nuclear realm. In 2019, the company obtained a site use permit from the DOE, and in February 2020, it snagged an agreement with Idaho National Laboratory (INL) to demonstrate down-blended HALEU in a commercial-scale Aurora reactor. Oklo is currently looking to put that project online within a 2026 or 2027 timeframe. It says it is meanwhile fostering a “robust pipeline of potential customer engagements across a number of industries and signed non-binding indications of interest that it believes could result in sales of over 700 MWe.”

In tandem, Oklo has made pioneering licensing steps. In March 2020, it submitted the first-ever combined license application (COLA) to the NRC for an advanced non-light water reactor (LWR) for the INL project. While NRC staff in January denied the application “without prejudice,” Oklo in September 2022 formally relaunched the licensing effort. In tandem, the company has kicked off regulatory activities for a first-of-its-kind nuclear fuel recycling facility that could produce commercial material from used LWR fuel by the early 2030s. Fuel recycling, a “complementary track” to its power production business, could unlock a market opportunity estimated to represent hundreds of billions of dollars with enough energy content in today’s used fuel to produce the power needs in the U.S. for more than 100 years, safely and with near zero carbon emissions,” it says.

Oklo’s impetus is the prospect of selling power “directly to customers, offering the flexibility to purchase clean, reliable power and delivering more favorable financial terms to an estimated $3 trillion market.” The business model, it says, is bolstered by a focus on small reactors, “which have a highly competitive expected project cost of less than $60 million for the 15 MWe plant, compared to large multibillion-dollar utility-scale projects pursued by competitors.” In a recent notable milestone, Oklo on July 11 entered into a definitive business combination with special purpose acquisition company AltC Acquisition Corp., positioning the company for public trading on the New York Stock Exchange. The transaction is expected to furnish the startup with $516 million in cash on its balance sheet to support its “go-to-market strategy,” including its first project at INL and a commercial-scale fuel recycling facility. “In the intermediate to longer term, the transaction is expected to have a positive impact on Oklo’s operating results, providing funding for the commercialization of its power plants, further technology integration, and developing economies of scale,” Oklo has said.

The “landmark” partnership with Centrus marks a new opportunity that spans “fuel production, manufacturing, and power off-take, exemplifying the early market interest in our scalable power plants and differentiated business model, involving selling power, not power plants,” noted Dr. Jacob DeWitte, Oklo’s co-founder and CEO. “This important collaboration is expected to facilitate several elements of our strategy to meet the growing demand for our powerhouses that stems from our pipeline of customer engagements across various industries,” he said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Correction (Aug. 30): A previous version of this article erroneously suggested the Aurora Powerhouse design uses heat pipes. While that was true for its original offering, Oklo’s uprated design (15 MW and more) is part of the Aurora liquid metal fast reactor product family. The design now uses different heat transport mechanisms (flowing sodium versus liquid metal in heat pipes) to allow significantly more heat to be transported from the fuel.