From Ideas to Assets: How Digital Solutions Provide Value Through Project Lifecycles

The digital age is upon us and the power industry is a key participant in this exciting time. Significant work routines and asset management processes have already been transformed. Power plant operations are among the areas where advanced technology has had a big impact.

Power plant lifecycles are complex. Power companies spend significant time and money evaluating electricity market supply and demand trends simply to understand if new or upgraded assets are needed. Then, decision-makers must review all the options before choosing the type of generation they want to use to fill gaps. The planning, designing, and executing of projects can take many years and often requires many millions or even billions of dollars in investments. Once construction is complete and units are commissioned, the assets are expected to last decades, which requires ongoing investments in operations, maintenance, and security. Finally, when assets near their end of life, decisions must be made on when and how to carry out the decommissioning process and repurpose sites. It’s truly an amazing journey from start to finish.

The fact that we live in a high-tech world today makes managing power plant lifecycles both easier and more difficult. When technology is designed well, incorporated into plants appropriately, and works properly, it can provide the data and insight needed to fine tune the most complicated operations, improving efficiency and maximizing profit. But when things go wrong, it can leave technicians and managers scratching their heads and feeling lost troubleshooting equipment and components that they may not fully understand. Still, the benefits far outweigh the risks, and outside experts are always available to help solve complex problems, allowing today’s advanced technology to help power companies reach broader goals, including improving reliability, enhancing sustainability, promoting decarbonization, and adding business value.

How Digitalization Has Changed the Power Industry

Energy and power companies are accelerating their digital transformation to manage new project ventures, lower operational risk, reduce downtime, increase efficiency, meet regulatory compliance, and remain competitive. Innovative software solutions are available today for the energy and power industry that enable intelligent planning, designing, and executing of projects, as well as operating, maintaining, and securing of assets.

For example, digital tools are available to help maintenance planners perform their jobs better. One innovative solution allows planners to understand and compare costs and hours for corrective, preventive, and condition-based maintenance. This allows teams to perform the right type of maintenance (Figure 1) to maximize productivity while minimizing cost. Managers can also collect and decipher data on overdue work orders to better understand the consequences of delays and prioritize future actions.

The success of complex engineering projects requires a connected digital ecosystem, where unstructured information is transformed into smart digital assets that increase efficiency and improve safety while lowering costs and delivering expected business returns. Innovative project engineers have found great value in all-encompassing project execution platforms. Rather than using a tangled web of in-house-developed tools, commercial software, and spreadsheets to manage projects haphazardly, leading organizations have found a centralized portfolio and project management environment more effective. Such a system seamlessly connects data between different disciplines, standardizes processes across an enterprise, and provides crystal clear visibility into the performance of every project in real time.

Sound health, safety, and environment (HSE) management is crucial to sustainable power plant operations. However, many power companies are still using paper, spreadsheets, and word processor tools to document and manage the execution of safety-critical plant processes. Information is often scattered in various folders and databases throughout the organization, reducing the effectiveness of programs and leaving companies vulnerable to regulatory scrutiny. Digital solutions are available to help minimize risks, and enable HSE and process safety teams to reduce incidents and effectively meet internal and external compliance requirements.

Forward-thinking operations managers are using digital tools to acquire a valuable, data-driven experience that encapsulates easily consumable, timely information regarding past events, present facts, and future predictions. These systems can seamlessly connect safety-critical operational processes, procedures, and permits; alarm management methodology; maintenance work orders; real-time and historical process data; engineering schematics; and technical documentation with laser scanning data, 3D models, and cybersecurity safeguards to enable a robust and comprehensive digital twin for the entire operation.

To bring it all together and maximize the value of these new digital capabilities, a system that delivers a unified, role-based view of the physical and digital realities across facilities is available. This integrated view provides real-time visibility into asset performance, safety, security, and quality to enable better-informed decisions that increase productivity, operational integrity, profitability, and sustainability. It features a digital infrastructure that connects data across the entire asset lifecycle, enabling managers to achieve more with digital twins, third-party software, and legacy systems.

Modernizing Legacy Systems

Anyone with a computer or cell phone knows that technology is constantly evolving. What passed for state-of-the-art several years ago may be considered obsolete today. While there are probably people in the world who still carry a flip phone, anyone with a smart phone could tell them that the new technology is far superior to the old and the capabilities of each are hardly comparable.

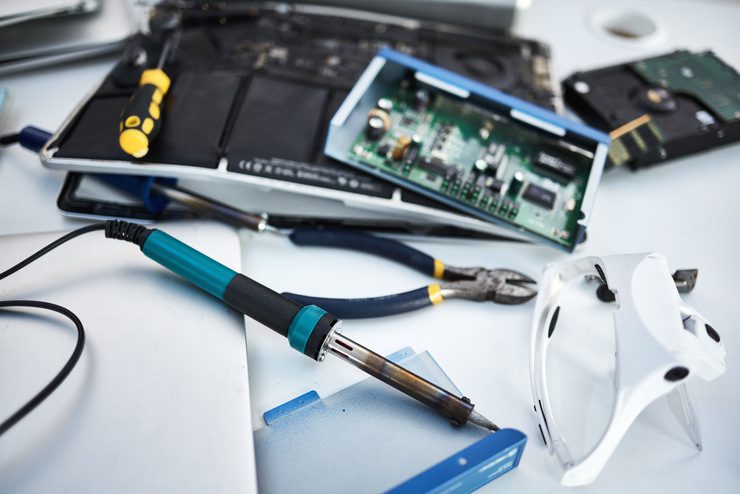

The same is true of technology in power plants. Operational technology (OT) and industrial control systems (ICSs) provide the backbone for power plant operations today. Both are generally part of a specialized hardware and software ecosystem used in industrial environments (Figure 2), including power plants, to monitor and control physical processes.

While OT and ICSs have been in use for decades, a lot has changed over the years. New OT systems benefit from advances in networking technologies, enabling greater connectivity and interoperability between different devices and systems. Better connectivity facilitates real-time data exchange, remote monitoring, and centralized management, leading to improved efficiency and decision-making.

Cybersecurity has also been improved over time. Traditional OT and ICS systems often lacked robust security measures, making them vulnerable to cyber threats. New OT incorporates stronger cybersecurity practices, including secure protocols, authentication mechanisms, encryption, and intrusion detection systems. This helps protect critical infrastructure from cyberattacks and ensures the integrity and availability of OT systems.

New OT also leverages concepts developed in the information technology (IT) domain, such as cloud computing, big data analytics, artificial intelligence (AI), and machine learning. With these improvements to OT systems, organizations can gain valuable insights, optimize operations, and enable more advanced automation. Modern OT architectures are also designed to be more scalable and flexible, facilitating easier integration of additional devices, sensors, and components, which allows companies to adapt to changing requirements without major disruptions.

But perhaps the biggest change in OT and ICS systems today involves analytics and decision-making enhancements. New OT systems can collect and process large volumes of real-time data from various sources, enabling advanced analytics, which empowers organizations to make data-driven decisions, optimize operations, reduce downtime, and enhance overall performance. Upgrading legacy systems for this reason alone could pay dividends.

Data, Data, and More Data

Power plant OT systems generate and collect a significant amount of data from various sources, such as sensors, meters, control systems, and monitoring devices. The data includes information about system pressures, temperatures, and flows; equipment status; environmental conditions; maintenance records; and more.

The volume of data generated and stored by all the power plants in the world is almost unfathomable (Figure 3). Large power plants or those with extensive monitoring systems may have many terabytes in their databases, depending on the plant capacity, and frequency and duration of data collection.

Yet, all this data is important and necessary to fully capitalize on the benefits of advanced analytics. That’s why it’s so important to eliminate unstructured, duplicated, and disconnected data and documentation, while ensuring data accuracy, integrity, and reliability. Consolidating digital data sources will reduce storage requirements, while still allowing intelligent information to be gleaned from databases. Investing in a comprehensive digital transformation strategy can accelerate a company’s continuous improvement efforts.

Workforce Challenges

Power companies are facing workforce challenges across the board. Some studies suggest the percentage of power industry workers eligible for retirement is as high as 40%, but finding replacement workers is difficult. For example, Public Service Enterprise Group Inc. (PSEG), a diversified energy company headquartered in Newark, New Jersey, had close to 500 active job openings in March 2023. While some of the openings were due to a growth in capital work, the company’s Chief Human Resources Officer reported a turnover rate on retirements of about 3% in 2022, which amounts to a lot of jobs in a workforce of about 12,500. Many other power companies have reported similar statistics.

In some circles, especially among younger generations, the power industry is perceived to be antiquated and boring, but that is far from the truth. As has already been noted, advanced technology and innovative systems are at the heart of most power plants. Furthermore, many power companies are addressing the workforce shortage by implementing new technology that captures and utilizes knowledge from soon-to-be retirees, and reduces the need for skilled labor.

Meanwhile, technology workers are in high demand, not only in the energy and power industries, but also in almost every other sector of the economy. The U.S. Bureau of Labor Statistics (BLS) predicts overall employment in computer and information technology occupations will grow 15% from 2021 to 2031, which is much faster than the average for all occupations. Furthermore, the BLS says the median annual wage for this group was more than double the median annual wage for all occupations in 2021, which is at least partly a reflection on the demand for these workers. While that may make it hard to hire in-house workers to implement and maintain OT and ICS projects, it shows the value of having a trusted contractor that has the experts needed to manage these systems.

Regulatory, Policy, and Stakeholder Considerations

Power companies have a keen focus on reliability and for good reason. Customers don’t appreciate it when their power is off. That’s why tools that improve reliability are so important.

There are many digital solutions available today that increase power plant reliability, and many more that are likely to be available soon based on AI and machine learning solutions. Yet, many observers worry about the effect AI may have on operations, especially how it could impact the workforce and jobs.

Regulators and policy-makers are contemplating the best way to provide oversight on AI applications. A Harvard Business Review (HBR) article suggested that the degree of trust in AI varies with the kind of decisions it’s used for. “When a task is perceived as relatively mechanical and bounded—think optimizing a timetable or analyzing images—software is regarded as at least as trustworthy as humans,” it said. “But when decisions are thought to be subjective or the variables change (as in legal sentencing, where offenders’ extenuating circumstances may differ), human judgment is trusted more, in part because of people’s capacity for empathy.”

In the OT world, AI will most likely be used more for “mechanical and bounded” decisions. Still, the HBR article said more stringent AI regulations “are on the horizon (at least in Europe and the United States).” With that in mind, companies will need new processes and tools, such as system audits, documentation and data protocols (for traceability), AI monitoring, and diversity awareness training to meet changing regulations. “A number of companies already test each new AI algorithm across a variety of stakeholders to assess whether its output is aligned with company values and unlikely to raise regulatory concerns,” the article notes.

Creating a Sound Digital Strategy

While it is always prudent to examine all options and chose a course of action only after weighing pros and cons thoroughly, there is significant risk in moving too slowly down the digital transformation path. Today’s power and energy markets are very competitive, and it’s easy to fall behind in the race to stay relevant.

To achieve their mission of supplying dependable electricity to customers around the clock, power companies must plan, design, execute, operate, maintain, and secure assets in a reliable, sustainable, cost-effective, and responsible way. To keep stakeholders happy, they must complete projects on time and on budget. Digital technology provides the tools necessary to accomplish those goals.

A sound digital strategy is required to effectively guide an organization’s digital transformation and leverage digital technologies. Among the first items companies must focus on is developing a clear vision with specific goals and desired outcomes. The digital strategy should articulate how digital technologies will support the organization’s overall objectives.

A company’s digital strategy must also align with its broader business strategy (Figure 4). A customer-centric focus is crucial, and it’s not always intuitive who the customers are. For example, customers for most power plant digital solutions will be internal to the company, rather than external. Operators and maintenance workers are often the people who will benefit most from technology being deployed at a power plant, so understanding their needs, preferences, and behaviors is necessary to ensure the technology selected is a good fit. Customer insights and feedback must be used help drive decision-making and shape digital deployment for these initiatives to be successful.

Given the rapid pace of technological advancements, a good digital strategy must embrace agility and flexibility. It should allow for iterative and incremental improvements, enabling the organization to experiment, learn, and pivot when necessary.

A data-driven approach is essential. In other words, decisions should have data behind them. This involves leveraging analytics, machine learning, and other data-driven technologies to extract insights, identify trends, and uncover opportunities for optimization and innovation.

A successful digital strategy prioritizes building organizational capabilities and fostering a digital culture. It involves ensuring the necessary talent, skills, and resources are in place to drive digital initiatives. It also promotes a culture of innovation, collaboration, and continuous learning, encouraging employees to embrace digital transformation.

Lastly, an effective digital strategy incorporates mechanisms for measuring and monitoring before and after performance. It establishes key performance indicators (KPIs) aligned with strategic goals and regularly assesses progress. It should also include considerations for security and risk management assessments. These hallmarks collectively contribute to a well-rounded digital strategy that positions an organization for success.

Taking the Next Step

Technology is constantly changing, and to keep up, power companies must change too. Incorporating innovative new digital technology into all aspects of a business will improve a company’s bottom line. Even before a decision is made to add a new asset to a company’s portfolio, technology can be used to evaluate options and provide insight on the best path forward. Digital solutions are available to enhance the planning, designing, and executing of projects. Once visions become reality, other solutions can improve operations, maintenance, and security. Throughout the full asset lifecycle, technology is the key to peak performance.

—Aaron Larson is POWER’s executive editor.