From a Distance, Power Sector Gets Up Close with Assets

The use of remote monitoring is enabling operators in the electric power sector to gain better insight into the real-time performance of equipment and systems.

Owners and operators of power generation equipment are working in a challenging environment, as more technologies are used to produce electricity, more generation facilities are sited in rural areas, and weather extremes threaten grid reliability and resiliency.

Remote monitoring of equipment is a key component in today’s operations and maintenance strategies. It’s a solution for many challenges faced by utilities and others in the electric power sector. It can give generating companies more peace of mind, providing the ability to audit, control, and troubleshoot generator sets through visual tools and mechanisms. Technology advancements mean this monitoring can be done from practically anywhere in the world, and in some cases with a device in the palm of the hand.

The use of digitization and the Internet of Things is now crucial to supporting peak performance in all manner of power generation plants (Figure 1), from coal-fired boilers to natural gas-fired turbines, from wind farms to solar arrays, to charging stations serving the ever-growing electric vehicle fleet. Such monitoring can provide needed real-time data, supporting historical information to see where performance is improving, and where it should change. Equipment can be analyzed to detect anomalies and enable proactive repairs. Key performance indicators (KPIs) can be customized across various types of hardware. Fuel levels can be noted remotely, and operating hours can be tracked. Monitoring also can provide weather conditions in specific areas.

“One of the key benefits of remote monitoring is that it empowers utilities and generating companies to do more with less—particularly in the area of experienced personnel,” said Rick Kephart, vice president of Technology at Emerson’s Power and Water Solutions business. “In the face of workforce shortages, companies are using remote monitoring technologies to centralize knowledge to take advantage of economies of scale. They can bring their best people into a central monitoring facility where those experts can monitor the long-term health of many plants at once. These groups can see the long-term effects of operation and degradation of equipment and use that data to predict failures, so emerging problems don’t become unexpected outages.”

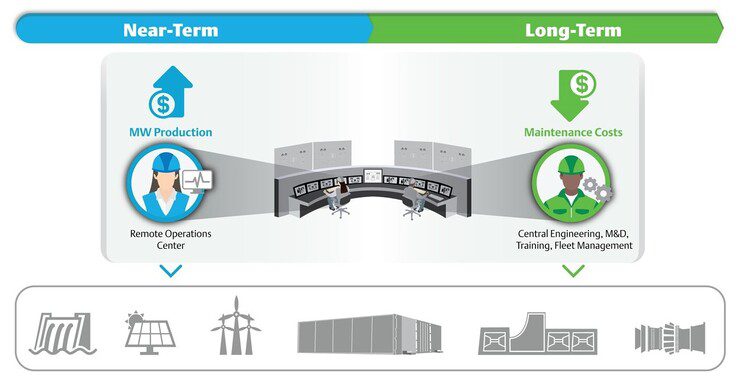

Having a remote monitoring plan in place can provide operators with updates on operating conditions and performance in real time. By supporting predictive maintenance, and helping optimize maintenance schedules, these programs can minimize downtime and reduce operational expenses (Figure 2).

“Safety and reliability—safety of the individuals that operate it, the asset itself, and the power grid as a whole—are paramount and take precedence over everything else,” said Julian McConnell, director of Owner’s Engineering at Bureau Veritas, a France-based group that works with the power generation sector. “There are different types of remote monitoring, and each has different strategies or drivers associated with it, but broadly speaking, some of the primary goals and drivers for remote monitoring include safety, reliability, operational efficiency, and pursuit of cost savings. Continuous remote monitoring helps utilities and power generators significantly lower their operational cost and equips them with better visibility into asset health and maintenance, which in turn helps increase the overall reliability and safety of the grid.”

Autonomous Control Brings Benefits

The benefits of remote monitoring are many. The ability to control assets autonomously means field workers may not have to be placed in remote, sometimes dangerous environments; instead, equipment can be checked from afar (Figure 3). The use of remote telemetry or remote terminal units, known as RTUs, are playing a key role, ensuring that assets between the point of generation and the consumer operate efficiently.

The diversity of today’s electricity sector, with more digitized and fragmented distribution systems, and different types of supply resources including energy storage, means that utilities need ways to collect, store, analyze, and act on data, providing the ability to make real-time decisions about the condition of their generation and grid assets and performance.

Ronald Hermans, offering manager for Smart Energy at Honeywell, told POWER, “Utilities and power generators should aim to achieve significant cost savings through remote monitoring, such as reducing the need for physical checks [truck rolls] and potentially requiring fewer or differently skilled operators. Safety enhancements are another key objective, with early warning systems and problem detection capabilities. Efficiency is also a primary goal, enabling faster and more optimal use of energy sources through real-time data and analytics.”

The advantages of systems such as RTUs, which can make it easier to detect anomalies and act on them more effectively, are that they can help quantify the cost of preventing outages and equipment downtime. Other technology, such as branch circuit monitors, can show real-time electrical capacity and power usage on various systems.

Kephart told POWER, “The benefits of a remote monitoring strategy are enormous. By following leading indicators, remote monitoring teams not only catch big problems early, but also help sites plan for more efficient, cost-effective outages. Teams can efficiently implement a planned outage at the optimal time to meet schedule constraints and are readily prepared with the right experts for the equipment that needs attention. While all these things can be accomplished with on-site maintenance and reliability personnel, that strategy is not only less cost-effective, but also difficult to accomplish with today’s worker shortages.”

Kephart noted the importance of remote monitoring outside of the traditional thermal power plant. “Remote monitoring becomes even more critical for today’s renewable energy generators,” he said. “Remote monitoring and control is the de facto standard for solar, which requires very limited operator intervention and has a tendency to be spread over wide areas. Keeping personnel at each site is rarely cost-effective. Instead, teams monitor these operations from a central site, then dispatch personnel as needed. Similar monitoring strategies are also common in wind generation and battery storage sites.”

Said McConnell: “Modern renewable generation assets that are brought online are equipped with some degree of monitoring. The question is how much is being monitored and then subsequently what is being done with that data in order to achieve the owner’s overall goals. It’s important to set up for success in remote monitoring by outlining the goals and requirements for remote monitoring, getting the right technology in place to support those strategies and objectives, and also creating operational procedures to support them.”

Finding Solutions

Several companies are involved in designing and developing remote monitoring structures for the power generation sector. The technology continues to evolve, with monitors able to communicate with telemetry data gateways connected to cloud computing infrastructure. That infrastructure includes software that helps operators better understand the performance of assets, to not only diagnose problems but also predict when they could occur.

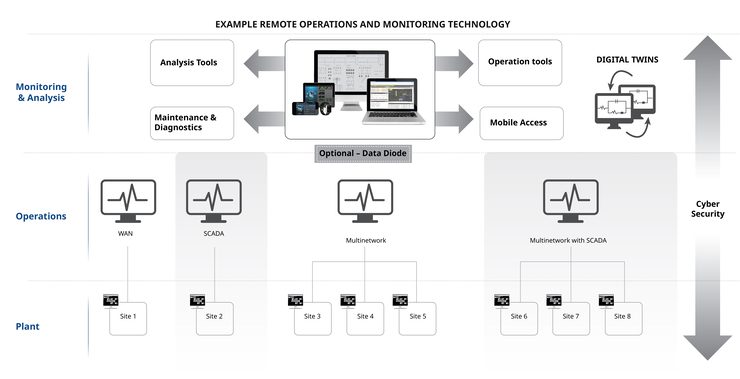

“Utilities need a wide range of solutions to effectively meet the remote monitoring and control needs of their fleets comprised of many different types of power generating and energy storage assets,” said Kephart. “To help customers meet these challenges, Emerson has leveraged its decades of experience in power generation to develop a full suite of advanced pattern recognition and machine learning [ML] technologies for remote monitoring and control [Figure 4]. Because technologies across sites are so different, these solutions support not only Emerson systems, but also control technologies from third parties.”

Hermans told POWER, “Honeywell offers advanced solutions for remote monitoring of power generation assets, including secure remote measurement, metering, and monitoring through Advanced Metering Infrastructure and SCADA [supervisory control and data acquisition] solutions. These are applicable in utility and process-related businesses. Additionally, Honeywell provides sophisticated building management solutions that encompass remote monitoring of power generation systems.”

“Eaton provides comprehensive, end-to-end digital solutions from edge to enterprise that offer precise measurement for informed decision-making, enabling utilities to accelerate the transition to a more modern, sustainable and resilient electric grid,” said Philippe Beauchamp, director of utility solutions at Eaton. “On the hardware side, we’ve integrated intelligence, sensors, and communication capabilities into essential electrical equipment such as reclosers, capacitor banks, and transformers to simplify the complexity of managing a two-way electric delivery system.”

Beauchamp said of Eaton, “At the grid edge, we’re helping T&D [transmission and distribution] utilities modernize critical infrastructure on a foundation of digital intelligence to manage the complexities of an increasingly electrified and decentralized grid. For example, our Grid Edge platform uses intelligent nodes to improve situational awareness and extend processing capabilities for applications ranging from high-voltage substation automation down to grid edge DER [distributed energy resource] management—reducing the burden on centralized systems and bringing visibility to areas of the grid that were previously not monitored.”

Kephart noted that his group’s Ovation automation platform analytic software and intelligence framework “provides the foundation for remote monitoring of energy asset health. Using the Ovation intelligence framework and analytic applications, maintenance and performance teams keep a close eye on the health of assets, tracking and trending their operation across time to know when to intervene before an issue becomes a costly problem. One of the key benefits of the Ovation analytics and intelligence framework is that under the hood it leverages AspenTech’s Aspen Mtell software that uses its machine learning engines to auto-learn normal and abnormal operation of assets for continuously improving predictive maintenance.”

Kephart continued: “The intelligence framework is scalable, where users can add software plug-ins to meet changing needs. One example plug-in is the Ovation plant prognostic advanced application that uses expert system-based analytics at the asset level to quickly identify impending process upsets or equipment anomalies and trigger mitigating action to avoid costly downtime or catastrophic damage. Teams can also add asset performance monitoring software to more closely examine overall efficiency and performance of energy generation operations.”

Cybersecurity Concerns

The experts who spoke with POWER noted cybersecurity is a chief concern around remote monitoring, as it is any time data is being collected and disseminated. Cyberattacks against utilities and power generators, including those directed at the grid, are becoming more frequent and present a growing threat to the electric power sector.

“Cybersecurity is a crucial concern in remote monitoring systems,” said Hermans. “Essential cybersecurity principles must be upheld, including confidentiality to prevent unauthorized data access, authenticity to validate data sources, integrity to protect data from tampering, non-repudiation to ensure data source accountability, and availability to guarantee continuous operation.”

Hermans told POWER, “Honeywell’s solutions are designed to address these security concerns, ensuring that remote monitoring systems are not only efficient but also secure. Honeywell recently became the first company to integrate Quantinuum’s Quantum Origin technology into smart utility meters to help the utility sector stay ahead of potential breaches. As cyberattacks on utilities surge, Honeywell’s initiative is setting a new benchmark for data security in critical infrastructures and ensures all gas, water, and electrical utilities’ operations remain uninterrupted.”

Allan Schurr, chief commercial officer for Enchanted Rock, a Houston, Texas–based company and leader in the design and construction of microgrids, said, “Cybersecurity is an essential consideration for all remote access microgrids. It starts with the right cyber architecture, technology design and selection, and operating procedures. Upholding best practices prevents intrusions and maintains system integrity.”

“As with all cybersecurity considerations for critical infrastructure, customers should follow best practices to protect their assets from cyber threats, [and] this includes remote monitoring,” said Emerson’s Kephart. “The most effective cybersecurity model we are seeing for remote monitoring today is using a data diode to air gap the control technologies at individual sites. With a data diode, all traffic is unidirectional—out of the control system. Because there is no path to access the control technologies themselves, remote monitoring technology using a data diode can even be set up on a public cloud.

“Most commonly, we are seeing organizations implement unidirectional data transfer to analysts, engineers, maintenance, and data science personnel, then manually relaying information to local people or remote operators to perform the necessary control moves to bring operations back in line,” said Kephart.

McConnell told POWER, “Cybersecurity is paramount when looking at remotely monitoring power generation assets. Regulatory compliance and adhering to applicable standards is going to be critical. There certainly are risks associated with remote monitoring operational technology systems and these systems do [like any other system] have vulnerabilities. It’s important to develop a good security architecture, employ robust mitigation strategies and put good preventive and detective controls in place, and then monitor those controls and systems appropriately.”

Kephart said remote monitoring, and tighter security standards, are more important as varied types of generation are implemented. Power producers and grid operators need more visibility around their assets as they balance supply and demand for both thermal and renewable energy.

“Because modern data diodes allow secure communication of health and performance data, remote monitoring, which has long been the standard in renewables generation, is now becoming much more common in fossil generation as well,” said Kephart. “The fossil sites still require more personnel on site but can much more easily take advantage of data science, maintenance, and engineering expertise at a remote command center where key personnel can quickly access multiple sites.

“It is also worth considering standards for ‘source of truth’ when considering implementing a remote monitoring or remote operations solution. Security data such as login administration, user rights, and more can be managed at the upper level or at individual remote centers,” said Kephart. “While either strategy is acceptable, it pays to know which strategy the company will embrace in advance of implementation.”

Finding Failures

According to Worldwide Power Products, a Houston, Texas–based company that serves several industries, including power generation, remote monitoring of generation equipment can help operators avoid problems that lead to the most common generator failures:

- Low batteries.

- Battery charger failures.

- Block heater failures.

- Shut-down alarms due to low coolant levels, leaks, etc.

- Low fuel supply.

- Operator error.

- Automatic transfer switch failure.

Those problems are just a snapshot; add to the list the variables of issues that can arise at renewable energy sites, and also along the power grid. Then there’s the need for more visibility of assets such as microgrids and other decentralized electricity generation equipment.

“Generator performance—whether measured by availability, efficiency, or emissions—necessitates monitoring of a wide array of operating parameters to ensure optimal performance,” said Schurr. “Distributed energy generated from microgrids is no different. By having continuous surveillance and analysis of incoming data, early indicators of deviation from standard operations can be detected and corrected before becoming a widespread issue.”

Schurr continued: “Distributed energy has two unique features that make remote monitoring even more valuable. They are typically unattended sites and are generally standardized; both features make comparing performance data and observed conditions even more insightful.”

Microgrids, as with other distributed energy assets, have their own management and control systems that also are evolving as decentralized generation grows. “Enchanted Rock monitors and manages over 300 operating sites including nearly 1,500 generating units and associated electrical equipment using our Granite Ecosystem microgrid platform from our Network Operations Center,” said Schurr. “We provide remote monitoring as a service to the asset owners, and also monitor and/or manage related on-site equipment and conditions that may include rooftop solar installations, weather and grid conditions, site security, market prices, EV [electric vehicle] charging circuits, and battery storage.”

Schurr continued, “Due to the nature of distributed energy resources, all microgrids require active remote monitoring to ensure high performance. Failure to detect anomalous conditions can compromise reliable operations, which will suboptimize maintenance dispatch and reduce operational and financial benefits from the microgrid.”

McConnell said there are situations not suitable for remote monitoring. “Complex physical processes or anything that could require complex physical inspections may be situations that may not always be suitable for remote monitoring. Additionally, anything that’s in a high-security area may also not always be suitable for remote monitoring.”

McConnell noted, though, that some instances almost always call for remote monitoring. “Remote monitoring becomes indispensable for equipment situated in remote or hard-to-reach areas, where physical access is challenging or poses safety risks,” he said. “For example, we’ve worked with renewable generation asset owners operating very remote facilities. Remote monitoring is key in these cases to ensure that on-site support is sent out only when necessary.

“Another example is for supporting large-scale operations. At scale, it’s going to be difficult to have enough boots on the ground to physically monitor everything. Remote monitoring becomes a necessity in these cases,” McConnell said.

Current Conditions and Future Needs

Power producers and grid operators know that technology advancements should help as they navigate an ever-evolving electric power landscape.

“When evaluating the benefits of remote monitoring, the key factors are less about suitable situations and more about delivering insights, actionable intelligence, and results to the right personas,” said Kephart. “For issues that might be sudden or catastrophic, teams need somebody nearby who can intervene. That can mean a control operator who is stationed onsite, but it can also mean prioritizing data delivery so that an operator in a remote control center has the information they need when they need it.

“Ultimately, the important factor is which persona the information goes to and what medium is used to deliver it. Short-term concerns must be delivered directly to an operator who can act quickly,” said Kephart. “Whether that can be done effectively in a remote operation is less about the response capability and more about the logistics of getting the data where it needs to go. Is there enough bandwidth to deliver that data on time? Is using that bandwidth cost-effective? These are the concerns that need to be answered on a case-by-case basis.”

The use of artificial intelligence (AI) also promises to further transform the electric power sector and its associated systems. “The rise of generative AI will likely have a dramatic impact on the future—and popularity—of remote monitoring,” said Kephart. “When organizations have a centralized operator watching many sites, that operator is responsible for sifting through and understanding large amounts of data. That typically takes expert personnel, which is why centralizing experts is one of the key drivers behind the growing popularity of remote monitoring centers.

“However, industry isn’t far from AI engines that will be able to work in tandem with these operators, ultimately acting as autonomous sentinels,” said Kephart. “Not only will such AI systems be able to point an operator’s attention to something they may have missed, but they will also provide prescriptive guidance to help with information processing and decision support. This future will open remote monitoring capabilities to personnel from a wider range of experience levels, essentially democratizing remote monitoring and, potentially, operation.”

McConnell agreed, saying that “AI and ML in conjunction with remote monitoring can provide greater insight in a variety of ways. In time, we’ll also see more integration of remote monitoring of generation assets with emerging technologies such as digital twins. Technology such as this is being deployed to enhance the way utilities and power generation asset owners monitor, manage, and interact with their assets. Emerging technology is going to need to be foundationally supported by remote monitoring, and data aggregation and cybersecurity will remain key to this ongoing transformation.”

“While remote monitoring offers broad benefits, situations requiring real-time intervention may necessitate local setups as a backup, as remote monitoring is more observational than operational,” said Hermans. “However, virtually all scenarios can benefit from remote monitoring for enhanced safety, efficiency, and cost-effectiveness. The focus should be on how remote monitoring can complement existing systems rather than it being a binary choice between suitability and necessity.”

—Darrell Proctor is a senior associate editor for POWER (@POWERmagazine).