TOP PLANT:

Jinzhai Pumped-Storage Hydro Facility Helps Integrate Renewable Energy and Solve Grid Stability Challenges

Jinzhai Pumped-Storage Hydro Facility Helps Integrate Renewable Energy and Solve Grid Stability Challenges

Pumped-storage hydropower is seen as a key technology in China to balance the grid and store excess energy from intermittent sources like wind and solar. The 1.2-GW Jinzhai pumped-storage project is a model for the industry and winner of a 2024 POWER Top Plant award.

Aaron Larson

The global energy storage market almost tripled in 2023, according to BloombergNEF. Last year’s record global additions of 45 GW and 97 GWh is expected to be followed by even larger growth this year. Globally, energy storage is set to add more than 100 GWh of energy capacity for the first time ever. The uptick is expected to largely be driven by growth in China, which is forecast to once again be the biggest energy storage market in the world.

When it comes to energy storage technology, batteries garner most of the attention. That’s not without good cause. The International Energy Agency (IEA) predicts grid-scale batteries will account for the majority of energy storage growth worldwide for many years to come.

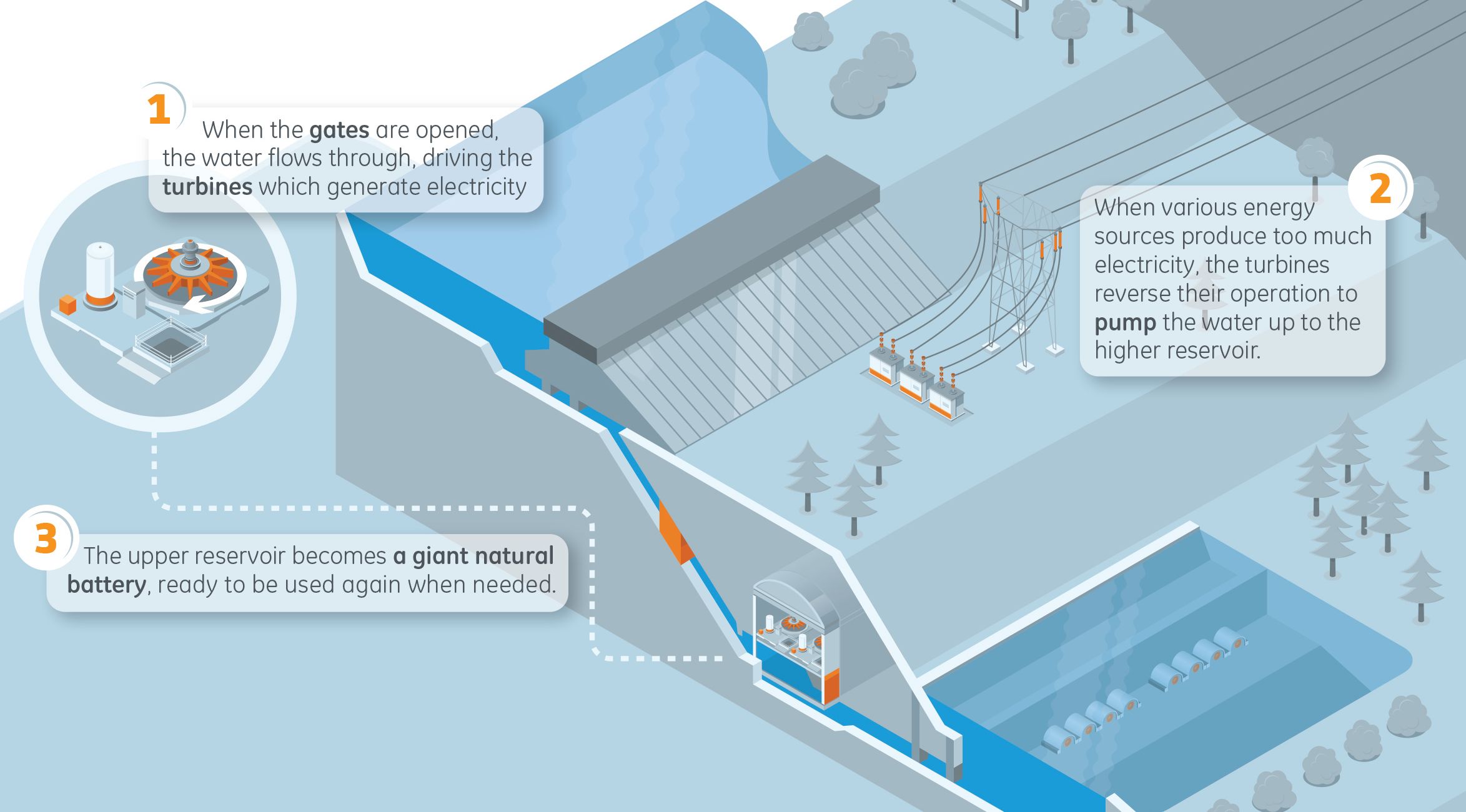

Yet, even as battery installations grow, pumped-storage hydropower (Figure 1) continues to account for the vast majority of current utility-scale energy storage capacity and capability—more than three-quarters of the world’s total at the end of 2023. According to the IEA, pumped-storage hydro had a total installed capacity of about 181 GW in 2023. Furthermore, the agency says there remains “significant additional potential” for pumped-storage hydro in many regions of the world.

1. Pumped-storage hydro functions to store energy by pumping water from a lower reservoir to an upper reservoir when excess electricity is available. When the energy is needed, the water is released from the upper reservoir and directed through turbines to generate electricity. Courtesy: GE Vernova

1. Pumped-storage hydro functions to store energy by pumping water from a lower reservoir to an upper reservoir when excess electricity is available. When the energy is needed, the water is released from the upper reservoir and directed through turbines to generate electricity. Courtesy: GE Vernova

Investments are being made in new pumped-storage facilities, albeit, mostly in China. The U.S. Energy Information Administration (EIA) reported that, as of May 2023, China had 50 GW of operational pumped-storage capacity—more than any other country—and it also had 89 GW of capacity under construction. Furthermore, the EIA said developers were “seeking governmental approvals, land rights, or financing for an additional 276 GW of pumped-storage projects.”

Collaboration Leads to Success

In Jinzhai County, Anhui Province, China, a new 1.2-GW pumped-storage hydro facility officially began commercial operation in December 2022. GE Vernova supplied the plant’s four 300-MW pumped-storage turbines and generator-motors, as well as the balance-of-plant equipment for the site. The facility is owned by Anhui Jinzhai Pumped Storage Power Co. Ltd., a division of State Grid XinYuan.

Power China was in charge of all civil work, grid, installation, and commissioning activities. In addition to engineering and manufacturing the plant equipment, GE Vernova’s scope of work also included supervising the installation and commissioning activities at the site.

“There has been an open, transparent, and strong collaboration amongst all stakeholders involved in the project, which greatly enabled the successful execution of the project to help meet the goals of Anhui Jinzhai Pumped Storage Power Co. Ltd. and State Grid Xin Yuan,” Zhiyong Liang, project manager with GE Vernova, told POWER.

The contract between GE Vernova and Anhui Jinzhai Pumped Storage Power Co. Ltd. was signed in December 2017. The four 300-MW pumped-storage units were commissioned between July 2022 and December 2022.

“The Anhui province was expecting one of the hottest summers ever,” Liang recollected. “State Grid XinYuan needed the Jinzhai pumped-storage plant to come to life before the heat waves to help increase the capacity of the grid system and get the population through this heated summer,” he added.

Safety First

“Safety is paramount and protecting people is the most important thing to do in everything GE Vernova does,” stressed Liang. “All stakeholders involved in these projects shared the same beliefs, standard, and processes to help deliver this project safely.”

The accelerated project schedule was the biggest challenge faced by the team, according to Liang, but it was not the only one. There were about 300 workers involved in construction. For civil works, and mechanical and electrical component installation, the workers were from the state-owned enterprises: Power China and Energy China. A systematic staff training process was implemented to ensure every worker was properly trained.

Like so many projects executed during this particular timeframe, the pandemic presented another obstacle. “COVID-19 just broke out at the beginning of year 2020 and ended at the end of year 2022,” noted Liang. “Throughout the pandemic, project execution was at its peak, from delivery to site installation and commissioning, and the execution has been affected. However, all participating parties did best to meet the challenges for the common purpose.”

Today, there are about 100 fulltime staff working at site—about half of them involved in daily operation of the units. GE Vernova said the Jinzhai plant was the world’s first application of a 13-blade runner in a pumped-storage hydropower project. Since the first unit started commercial operation in July 2022, all units have operated very stably and have fully achieved annual operating targets. The general efficiency of units reached almost 82%, Liang reported, which was higher than expected, creating additional value.actio

Positive Feedback

Concerning GE Vernova’s product quality, delivery process, and onsite service, Jie Zhai, vice dean of the Mechanical and Electrical department with Anhui Jinzhai Pumped Storage Co. Ltd., said, “Our overall evaluation was very satisfactory. Under the leadership of [the] project manager, the entire GE Vernova project team completed Jinzhai project in an excellent and efficient manner with a strong sense of compliance and project execution controls in place. GE Vernova’s proven technical solutions provided performance reliability and its onsite commissioning staff showed a high level of technical expertise and strong sense of responsibility, leaving us very satisfied.”

Delou Wang, Chief Engineer of Jinzhai project with Power China Huadong Engineering Corp. Ltd., agreed. “Through these years of cooperation with GE Vernova, I think the company’s project management system and HSE [health, safety, and environment] systems are very comprehensive, and the process controls for Jenzhai project were very good,” he said.

Zhanle Han, Chief Engineer of Jinzhai project with Power China Sinohydro Bureau No. 5 Co. Ltd., was impressed with GE Vernova’s onsite response capabilities. “GE Vernova responded quickly to problems reported onsite, and solved problems thoroughly and efficiently,” said Han. “GE Vernova’s field service team is very professional in solving onsite problems. Instead of just sending feedbacks to headquarters as a megaphone between front and rear, they could independently solve actual problems onsite.”

“I remember, during execution, a small forging defect was found in the lower shaft of [a] generator-motor,” Wang recalled. “In order to avoid stress concentration during the repair process for such defects, GE Vernova made a prompt decision to scrap this shaft. This shows the company’s high standards and requirements regarding quality.”

“What most impressed me was probably the onsite commissioning supervisors. Basically, every day after we finished commissioning, it was usually very late, but GE Vernova’s commissioning supervisors would still stay voluntarily to check the status of the equipment,” said Zhai. “Their dedication and high sense of responsibility inspired the entire onsite commissioning team.”

A Vital Resource for Renewable Energy Integration

The 1.2-GW Jinzhai pumped-storage hydropower plant project will play a key role in China’s journey to a stronger energy mix. The project’s annual generating capacity represents about 1.4 times the annual household electricity consumption in Jinzhai. Acting as a sustainable giant energy storage system, the Jinzhai pumped-storage station will save up to 120,000 tons of coal and reduce 240,000 tons of carbon dioxide emissions each year, according to GE Vernova.

“Pumped-storage can generate and store a large amount of renewable energy, at unprecedented scale, and dispatch it when needed,” Liang said. “Pumped-storage supports the integration of solar and wind power, helping to stabilize the grid when the sun doesn’t shine or the wind doesn’t blow.”

Compared to other alternatives, such as batteries, compressed air energy storage, and flywheel energy storage, pumped-storage hydro stands out for its large capacity and long lifespan. It is particularly well-suited for grid-scale energy storage and balancing intermittent renewable sources. While pumped-storage hydro requires a suitable location to work, projects like the Jinzhai facility show that the technology is a great option when the right conditions exist. As such, POWER recognizes Jinzhai and the team that engineered and constructed it with a 2024 Top Plant award.