TOP PLANT:

Ohio Facility Supports PJM Power Supply in Heart of Major Shale Plays

Caithness Energy’s Guernsey Power Station, which features GE Vernova equipment, is an important gas-fired facility helping replace retired coal-fired generation in the PJM Interconnection territory.

Pumped-storage hydropower is seen as a key technology in China to balance the grid and store excess energy from intermittent sources like wind and solar. The 1.2-GW Jinzhai pumped-storage project is a model for the industry and winner of a 2024 POWER Top Plant award.

Darrell Proctor

Officials with the PJM Interconnection, the regional transmission organization serving 13 states including Ohio, last year warned that power plant retirements in that territory could lead to power shortfalls. That led to much hand-wringing among regulators and policymakers, as officials expressed concern about how to bring new generation capacity online fast enough to avoid that situation.

One answer was to add new natural gas–fired generation. The PJM territory includes major shale gas plays, such as the Marcellus and Utica, providing a ready-made supply of feedstock for gas-fired power plants. Officials noted an important consideration for new power stations would be utilizing the latest, most-efficient technology, in order to satisfy not only power demand but also meet environmental regulations.

Enter the 1,875-MW Guernsey Power Station, located in Guernsey County in southeastern Ohio. The plant was built on property that included an existing 42-inch Rockies Express Pipeline and AEP’s Kammer-Vassell 765-kV transmission line. The plant, operated by Caithness Energy, a privately held independent power producer based in New Jersey, came online in June of last year and immediately became a model for how the PJM can add capacity to meet the expected increase in power demand in the region.

Officials said Guernsey, along with other planned electricity projects, could help alleviate concerns about resource adequacy and grid stability across PJM. The plant features advanced technology, including three GE Vernova 7HA.02 gas turbines (Figure 1) in a single-shaft combined cycle configuration. Officials said it’s the largest set-up of this kind at a U.S. gas-fired power plant.

1. The Guernsey Power Station utilizes three GE Vernova 7HA.02 gas turbines in a single-shaft combined cycle configuration, the largest set-up of its kind in a U.S. power plant. Courtesy: GE Vernova

1. The Guernsey Power Station utilizes three GE Vernova 7HA.02 gas turbines in a single-shaft combined cycle configuration, the largest set-up of its kind in a U.S. power plant. Courtesy: GE Vernova

“Caithness is proud to deliver this state-of-the-art electric generating solution to provide energy and capacity to the PJM market,” said Ross Ain, Caithness Energy’s president, at a ceremony marking commercial operation of the Guernsey plant. “Our project is cleaner and more efficient than older plants. It will provide reliable energy with minimal impact on the environment by utilizing a significantly more efficient technology to produce energy, thereby significantly lowering carbon and other emissions compared to older plants and utilizing a dry cooling system that reduces water use by 95% compared to older facilities.”

$1.6 Billion in Financing

Caithness Energy and Florida-based Apex Power Group secured $1.6 billion in financing for the project from Investec Bank, BlackRock, and AMP Capital in September 2019. The Guernsey plant was built by Connecticut-based Gemma Power Systems, an engineering, procurement, and construction company, and a wholly owned subsidiary of Maryland-headquartered Argan, along with several subcontractors from Ohio and elsewhere.

Officials said that in addition to the typical challenges that all large construction projects face, the Guernsey Power Station was built over abandoned room and pillar coal mines that were required to be filled in prior to constructing the facility. In addition, construction of the project occurred during the global COVID-19 pandemic, which impacted manpower and resulted in significant supply chain challenges. Officials said all the challenges were overcome with a minimal overall impact to project completion.

William F. Griffin Jr., CEO of Gemma, in a statement said, “We are thrilled to have the opportunity to help deliver clean, reliable energy to Guernsey County and the greater Ohio community.”

The GE Vernova turbines at Guernsey power three W84 generators, three STF-A650 steam turbines, and three GE Vernova triple pressure with reheat heat recovery steam generators, which include supplemental duct firing, state-of-the-art selective catalytic reduction technology for reducing NOx emissions, and an oxidation catalyst for reducing carbon monoxide and volatile organic compounds (VOCs). GE Vernova maintains the facility under a 20-year services agreement, and provides cloud-based predictive analytics through GE Vernova’s Asset Performance Management (APM) software. This APM Reliability software, powered by SmartSignal, will help predict potential asset failures and reduce unplanned downtime, while improving power plant productivity and reliability.

Officials have noted that GE Vernova’s H-class gas turbine technology is considered among the most responsive and flexible in the industry. It has set combined cycle efficiency records at both 50-Hz and at 60-Hz stations. GE Vernova has said, “The economies of scale created by the 7HA gas turbine, combined with its 64% combined-cycle efficiency, enable the cost-effective conversion of fuel to electricity to help power plant operators meet increasingly dynamic power demands.”

“We are proud that our advanced HA combined cycle equipment started to provide efficient, flexible and reliable electricity at Guernsey Power Station,” said Dave Ross, president of GE Vernova’s Gas Power in the Americas region. “Gas power plays a crucial role in the energy transition, helping to balance the variable nature of renewables and ensuring system reliability. Our 7HA.02 gas turbines, which can burn up to 20% hydrogen with plans to transition to 100% hydrogen over the next decade, are a highly efficient energy solution to help power plant operators, like Caithness Energy, to advance their carbon emissions reduction goals. In addition, our services and digital solutions will be crucial to improve Guernsey plant’s performance and availability.”

GE Vernova said the flexibility of the 7HA suite of gas turbines “enables increased dispatch and ancillary revenue, while enhanced fuel flexibility accommodates a wide range of gaseous fuels [shale gas, high ethane, hydrogen] and liquid fuels [#2 diesel, crude oils]. The 7HA gas turbine ramps up to full load in 10 minutes and features a novel configuration that supports simplified installation and maintenance.”

Ain said, “GE Vernova’s gas turbines are among the largest and most-efficient gas turbines in the world, and operating flexibility may be considered as the key feature of Guernsey plant ... we trust GE Vernova’s equipment will help us turn current energy transition challenges into the opportunity to drive carbon emissions reduction in the energy sector through the deployment of new flexible, much more efficient, and cleaner gas-fired plants to substitute for older, less-efficient units.”

Innovative Cooling Technology

The plant utilizes dry air cooling technology from Belgium-based SPG Dry Cooling. The system reduces water consumption by up to 95% compared to a conventional water-cooled plant.

Other companies involved in the construction of the Guernsey station include Howard Concrete Pumping for mine mitigation, EPC Services Company for the 765-kV switchyard, and Baker Concrete Construction for foundations. POWER Engineers, a consulting engineering group with offices across the U.S., served as the project’s engineer of record. Water and sewer infrastructure for the project was provided by the Village of Byesville, and the Guernsey station purchases water and sewer services from Byesville.

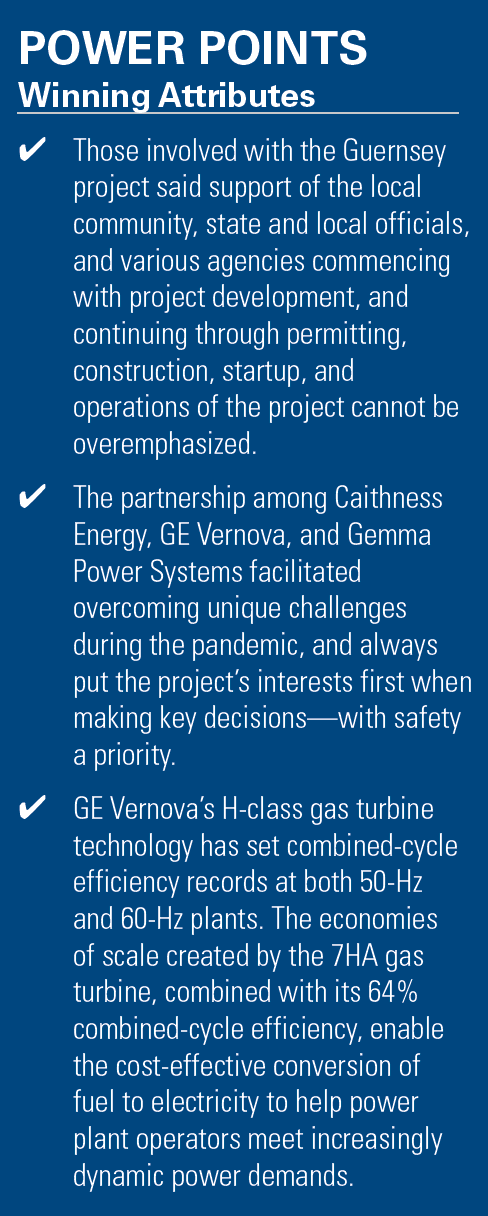

The June 2023 ribbon-cutting event marking commercial operation of Guernsey featured several groups involved with the project, including elected officials, economic development organizations, and project partners who participated in the development, financing, construction, equipment and fuel supply, and operation of the facility. Officials noted that during construction, and continuing during operation, financial support was and is being provided to local non-profit groups, including food banks and other community organizations and activities. Two local fire departments also each received a check for $50,000 to support their services to the area. Those involved with the project said that support of the local community, state and local officials, and various agencies commencing with project development, and continuing through permitting, construction, startup, and operations of the project cannot be overemphasized.

“We have worked closely with our partners, suppliers and contractors to build this important project, overcoming the many challenges of doing so during the pandemic,” said Ain. “Guernsey County has benefited directly from nearly 1,000 skilled craft workers at peak construction and approximately 30 permanent high-tech jobs, all while committing to provide vital funding to the Rolling Hills Local School District, which has enabled a major school construction project.” n